Other couplings for oil and gas industry

Other couplings for oil and gas industry – general information

In addition to HAMMER LUG unions, many other specialist couplings are used for oilfield service. They include: API flange couplings, special mud tank couplings. Many connections use NPT imperial pipe thread compliant with API 5B requirements (sometimes designated as API LP – Line Pipe thread).

API flange couplings

High pressure flanges used in the oil and gas industry for connecting pipelines, in particular:

- on wellheads (CHRIS™AS TREE);

- on blowout preventers (BOP).

Flange faces are grooved and compatible with type R, RX and BX sealing rings. Manufactured according to API standard from carbon steel, working pressure up to 1380 bar depending on the type of flange.

API flange sealing rings

RTJ (Ring Type Joint) metal ring gaskets are designed to seal API 6A flanges with a groove. Made of low-carbon steel as standard. Optionally in cast iron, stainless steel, Duplex steel, Inconel and Hastelloy alloys, titanium. The hardness of ring gasket material should always be lower than that of the flanges to be sealed. When the flanges are bolted together, a high surface stress develops on the contact area between the flange and the ring gasket. This process leads to plastic deformation of the ring gasket which seals the connection under high pressure or high temperature conditions.

Additionally, as the pressure of the medium inside the ring rises, the ring gasket stretches elastically and seals the connection even better.

Steel sealing rings used in API high pressure flanges:

- type R with octagonal or oval cross-section (working pressure up to 700 bar);

- type RX with octagonal cross-section (working pressure up to 750 bar);

- type BX with octagonal cross-section (working pressure up to 1500 bar);

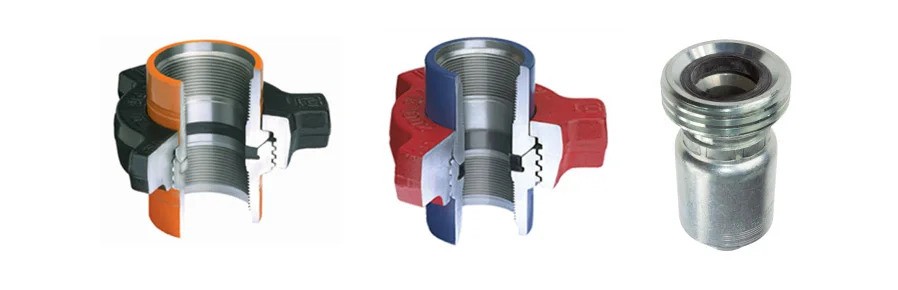

Mud tank couplings

Couplings for mud tanks are used in drilling operations around the world. The connection between the steel mud tank and the piping system must be leak-tight and quick to disconnect, for pipe diameters from 4 up to 16 inches. There are two types of connections:

HAMMER SEAL unions, threaded: the part with male thread is welded to a tank, while the nut with female thread and O-ring, which is placed on a pipe, presses the O-ring to the pipe surface, sealing the connection;

SEAL-O-GRIP union, inflatable: welded to a tank, has an air-inflatable seal which inflated to several bar pressure presses against the outer surface of a pipe, sealing the connection.

In both cases, the pipe is inserted into the opening of the union, and the connection is sealed on the outer surface of the pipe. Both unions are designed for low pressure service (up to about 10 bar) and provide leak-tight connection, even if the pipe is not perfectly aligned.

Valves for oil and gas industry

Specialised valves for the oil and gas industry:

plug valves for drilling fluid, water, cement, etc. For high pressure applications including fracturing and cementing operations. Sizes from 1 ” to 3″, fitted with HAMMER LUG unions Figure 1502. Working pressure up to 1034 bar (15000 PSI). A version for sour gas service is available.

LS ball valves in sizes from 1/4″ to 1″, in AISI316 stainless steel, high corrosion resistance, also for sour gas service. NPT thread end connections, working pressure up to 207 bar.

Swivel unions

Swivel joints designed for oilfield service, either with two (SR type – SHORT RADIUS) or three (LR type – LONG RADIUS) rows of ball bearings, intended for drilling mud pipelines, water, cement, abrasives pipelines etc. Suitable for flushing, fracturing, cementing operations, choke and kill lines, etc. Made of chromium-molybdenum steel in sizes from 1″ to 3″, in various rotating joint configurations, with HAMMER LUG unions or NPT thread end connections. A version for sour gas service also available. Working pressure 414 bar (6000 PSI) for SR type, 1034 bar (15000 PSI) for LR type.