Pressure metal hoses

Pressure metal hoses – general information

Flexible metal hoses are manufactured of corrugated sheet metal made of austenitic stainless steel (AISI 321, AISI 316L) in a process of mechanical forming or hydroforming. Used in high temperature conditions – even up to several hundred degrees (hot water, steam, oil, high ambient temperatures), for low temperatures (cryogenic gases), for technical gases (e.g. oxygen, argon, helium) and many other chemical substances.

The working pressure ranges up to several hundred bar depending on hose type, diameter and temperature. Suitable for cyclic bending conditions under pressure (service life of 50000 cycles confirmed in accordance with ISO 10380 standard conditions).

There are version with AISI 304 stainless steel braid, without braid or with double braid, nominal diameters ranging from DN6 up to DN250.

Used as complete hose assemblies with carbon steel or stainless steel fittings welded to the hose. The highest quality of steel hoses and hose assemblies welded in Tubes International is confirmed with certificates issued by Germanischer Lloyd, Det Norske Veritas and Office of Technical Inspection (UDT) within the scope of compliance with Pressure Equipment Directive 97/23/EC.

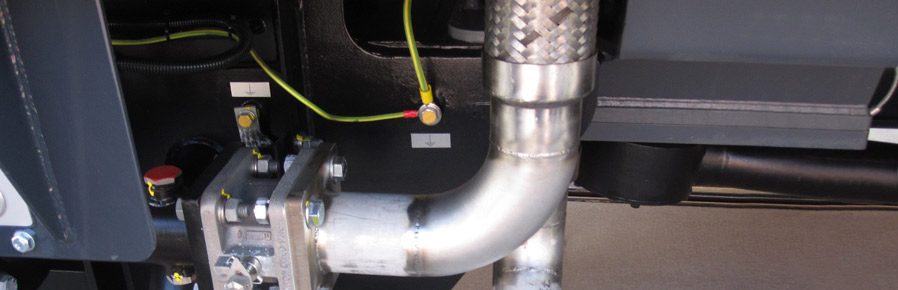

Flexible metal hose assemblies with fittings

Ready for use, complete hose assemblies made out of metal pressure hoses with welded fittings (made of carbon steel, 304 and 316/316L stainless steel). Hose assemblies with standard threaded fittings, flange, pipe and other fittings. With BSP, BSPT, NPT pipe thread, metric thread and UNF imperial thread. Fixed or swivel flanges according to PN-EN 1092-1 (DIN PN), also flanges according to ANSI B 16.5 American standard . Special fittings are produced to customer order always as fast as possible. The hose assemblies with soldered brass fittings are also available.

The fittings are welded by our certified welders in the atmosphere of shielding gas, under controlled production conditions. The highest quality of steel hoses and hose assemblies welded in Tubes International is confirmed with certificates issued by Germanischer Lloyd, Det Norske Veritas and Office of Technical Inspection (UDT) within the scope of compliance with Pressure Directive 97/23/EC.

There is also a group of flexible steel hoses assemblies heated with e.g. steam, with double-jacket design (see heated hoses group).

When a steel hose assembly is selected, besides working pressure, temperature and chemical resistance, also remember about the conditions required to connect the hose assembly to the installation, especially about the length, position, minimum bending radius – particularly if the installation moves. It is recommended to prepare a dimensional sketch of the installation.

The most important features of pressure metal hoses

The most important features of pressure metal hoses:

– resistance to ageing, heat, oils and hydrocarbons, many chemicals, steam, hot water, etc.

– wide temperature resistance range (from -270°C to +700°C)

– non-flammability

– high pressure and vacuum resistance

– impermeability to penetrating gases and fluids

– flexibility at large diameters and low temperatures, resistance to kinking

– high electrical and thermal conductivity

– permanently fixed fittings, relatively safe course of destruction in case of breakdown.

Correct selection, installation and handling

Due to specific construction of pressure metal hoses, selection and installation of the hose should be carried out in consultation with Tubes International.

Note:

– always follow installation and handling instructions given in the manual,

– never twist the hose during installation and operation,

– dynamic flexing must be determined and taken into account,

– material of the hose and fittings must be defined by the corrosive effect of the medium and the external environment,

– occurrence and effect of vibrations have to be considered,

– at very high flow rates, the corrugated hose construction causes turbulence, large pressure drop, and sometimes dangerous vibrations,

– make calculations using a temperature correction factor – working pressure data in the tables is based on an ambient temperature +20°C.

Metal pressure hoses according to ISO 10380

ISO 10380 specifies the requirements for the design, manufacture, testing and installation of pressure metal hose assemblies. In terms of service life, the standard divides hoses into four classes. Tubes International offers hoses that meet an average service life requirement of 50 000 flexing cycles.

Material of metal hoses

Basic, most common metal hose materials:

- AISI 304 stainless steel (braid)

- AISI 321 stainless steel (hose)

- AISI 316 L stainless steel (hose and braid)

- copper alloys: bronze (hose and braid, used up to 200°C)

- nickel alloys: Monel, Inconel (hose and braid, used for high corrosion resistance,

especially to chlorine)

Assembly of metal hose fittings

The fittings of flexible pressure metal hoses are assembled to the hose by:

- screwing (a special type of reusable fitting allow installation directly on system connections; limited pressure parameters),

- brazing with soft and hard solder – limited temperature resistance,

- TIG welding – the most common assembly method.

Steel hose fittings are made of carbon steel, AISI 304 and 316 stainless steel, nickel alloys and copper alloys (brass, bronze).

NOTE! Carbon steel fittings must not be used for temperatures below -20°C and above +400°C.