Heated hoses

Heated hoses – general information

Hoses heated with a heating agent (steam, hot water, heating oil) are intended for the transfer, loading and unloading of substances that conveyed through the hose, must be heated, melted and kept at constant, elevated temperature. Application for such media as: oil, grease, wax, resins, paints, granulates, chemical substances, adhesives, food products They can substitute electrically heated hoses in applications where such heating agents as technological steam or heating oil are easily accessible or where electrical power supply is not acceptable or not recommended. Frequently used for the loading/unloading of rail tankers, operation in potentially explosive atmospheres is also possible.

A braided PTFE or steel hose is used as a base hose. A heating hose (PTFE or of other plastic material) is wound around this hose. The hose assembly has thermal insulation layer, outer cover and end caps. The inlet and outlet of the heating hose can be on one side or on both sides of the hose assembly.

Excellent CORROFLON or BIOFLEX ULTRA PTFE process hoses are available as CH version as well. These hoses may be equipped with fittings with PTFE liner extended through the fitting and flared out on the sealing face. Used in the food industry and for loading/unloading of hazardous chemical substances.

There is also another heated hose type, a jacketed hose (a double steel hose – the base hose is in the outer heating hose, a jacket). These hoses are made using metal pressure hoses.

Hose construction

Base hose

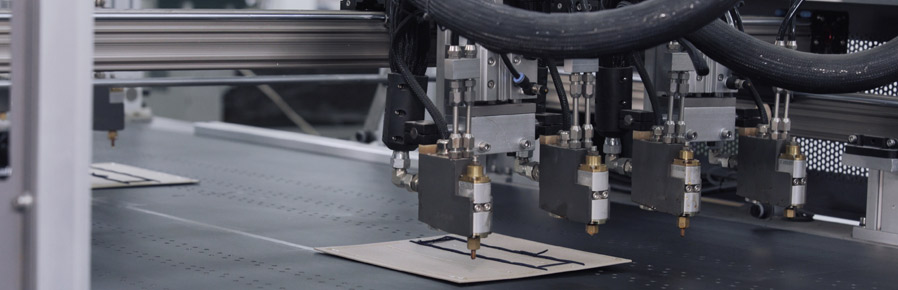

ETH, Electrically Trace Heated hoses are intended for the transfer, loading and unloading of substances that conveyed through the hose, must be heated, melted and kept at constant, elevated temperature. Application for such media as: oil, grease, wax, resins, hot melt adhesives, paints, granules, food products. They are extensively used for hot melt adhesive dosing. Optionally manufactured as EX approved, according to ATEX directive for use in potentially explosive atmospheres. There is also a heated twin hose designed specifically for polyurethane foam production and hoses for exhaust analysis systems.

Electrically heated hoses are composed of:

- base hose (hose assembly) with fittings, resistant to pressure, temperature and medium flowing through;

- heating element and temperature sensor;

- thermal insulation;

- outer cover and hose end caps;

- connecting cable, plug and temperature controller.

Hose construction

construction electrically heated hoses

The base hose is chosen depending on the working pressure and medium output required. PTFE hose in stainless steel braid is the most common. The material of this hose features outstanding chemical and temperature resistance (up to 250°C), and very low coefficient of friction. At temperatures above 250°C steel hoses are used.

Fittings

The hose fittings (threaded, pipe or flange) at both hose ends are selected according to customer’s specification. Tubes International supplies the electrically trace heated hoses with virtually all types of fittings available on the market.

Heating element and temperature sensor

Heating element and temperature sensor are helically wound around the base hose. The power of the heating element depends on the temperature that must be maintained, the diameter and length of the hose. Supply voltage is usually 230 V (optionally 12 ÷ 500 V). As a standard temperature sensors of PT100 type are used, type J and K thermocouples, though other sensors are also available, e.g. NI120, NTC.

Thermal insulation

The type of thermal insulation depends on working temperature. Elastomer foam is used for temperatures up to 100°C, silicone foam up to 250°C, fibreglass insulation for higher temperatures.

Outer cover and hose end caps

Polyamide braid is usually applied as the outer cover, but steel braid, polyurethane braid, silicone braid or fibreglass braid are also available. There are two hose end cap options: hard and soft. The hard caps made of polyamide reduce free, flexible hose length between the fittings, but also reduce the load on the spot of critical fitting-hose connection. Elastomer soft caps, due to their flexibility, are recommended for short hoses.

flexible heated hoses

Standard polyamide braid

Corrugated polyamide heated hose

Corrugated polyurethane hose

Fibreglass braid heated hose

Fibreglass braid

Corrugated polyamide heated hose

Corrugated polyamide hose

Stripwound metal heated hose

Stripwound metal hose

Steel braid heated hose

Steel braid

Silicone rubber braid heated hose

Silicone rubber braid

End caps

End caps come in two varieties: hard and soft. Polyamide hard caps reduce the free, flexible length of the hose between the fittings, but also reduce the load on the place where the fitting connects to the hose. Soft caps made of elastomer are recommended for short hoses due to their flexibility.

hard cover for an electrically heated hose

Hard caps

soft cover for an electrically heated hose

Soft caps

Connecting cable, plug and temperature controller.

The electrically heated hose is equipped with a connecting cable e.g. 1,5 m long with or without plug. The hoses can be used with a temperature controller of the customer or supplied with various types of temperature controllers including the simplest mini controllers built into the hose but also multi-channel controllers serving several hoses.

Customised solutions

Rubber hoses with an integrated heating system

The electrically heated rubber hoses make a group of very peculiar hoses – the heating element is wound onto the internal rubber hose layer and vulcanized. The temperature sensor reads the temperature directly in the hose wall. The hose is not visually different from a standard rubber hose. These hoses (e.g. made of NBR rubber) are used particularly in food industry to transfer fats and other food products.

CORROFLON and BIOFLEX ULTRA PTFE electrically heated hoses

They are made using excellent CORROFLON or BIOFLEX ULTRA PTFE process hoses as a base hose. These hoses may be equipped with fittings with PTFE liner extended through the fitting and flared out on the sealing face. Used in the food industry and for loading/unloading of hazardous chemical substances.